|

|

|

|

|

|

|

|

| |

|||||||

| |

|||||||

| |

|

|

|

|

|

|

|

|

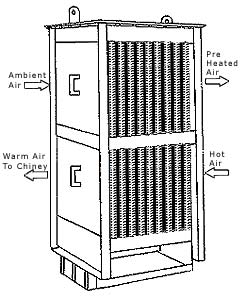

Use of Gravity Assisted Heat Pipe complies orientation

evaporator above condenser for the Heat Pipe Heat Exchanger.

|

|

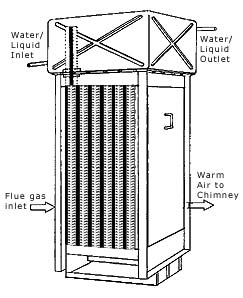

Air to liquid Heat Pipe Heat exchangers

This heat exchanger resembles Air to Air unit, only difference is liquid/water tank is provided at the condensation section to preheat liquid/water. |

|

|

ADVANTAGES OF HEAT PIPE HEAT EXCHANGERS Saving in fuel consumption |

Application AreaBoiler |

Information needed from you:

. Type of your Equipment

. Fuel Used

. Flue Gas Flow Rate Kg/hr.

. Fuel Quaintly

. Flue Gas Temperature Dig. C

. Medium To be heated Air/Water

. Flow Rate of medium (Air/ Water) Kg/hr.

. Temperature of medium (Air/Water) Dig. C

. Chemical composition of flue gas if available